Value Chain in Textile Industry

Muhammad Ibrahim Khalilullah

Department of Textile Engineering

Daffodil International University

Email: ibrahim23-3123@diu.edu.bd

Value Chain:

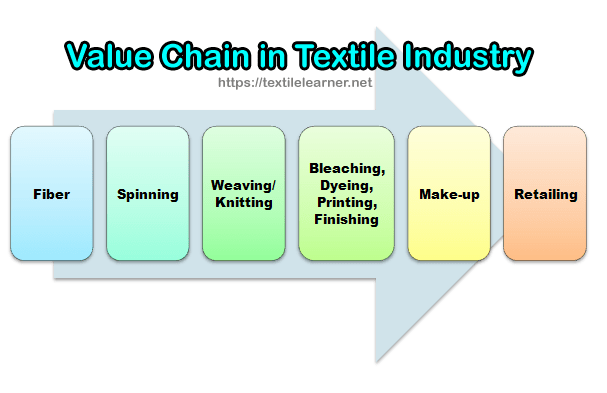

A value chain is a set of activities that a firm operating in a specific industry performs in order to deliver a valuable product or service for the market. The concept comes from business management and was first described and popularized by Michael Porter in1985. Textile, a versatile basic necessity turns into a luxury brand having a long value chain. Value chain in textile industry is shown in below figure.

Primary Activities:

1. Inbound Logistics – involve relationships with suppliers and include all the activities required to receive, store, and disseminate inputs.

2. Operations – are all the activities required to transform inputs into outputs (products and services).

3. Outbound Logistics – include all the activities required to collect, store, and distribute the output.

4. Marketing and Sales – activities inform buyers about products and services, induce buyers to purchase them, and facilitate their purchase.

5. Service – includes all the activities required to keep the product or service working effectively for the buyer after it is sold and delivered.

Supply Activities (Secondary):

1. Procurement – is the acquisition of inputs, or resources, for the firm.

2. Human Resource management – consists of all activities involved in recruiting, hiring, training, developing, compensating and (if necessary) dismissing or laying off personnel.

3. Technological Development – pertains to the equipment, hardware, software, procedures and technical knowledge brought to bear in the firm’s transformation of inputs into outputs.

4. Infrastructure – serves the company’s needs and ties its various parts together, it consists of functions or departments such as accounting, legal, finance, planning, public affairs, government relations, quality assurance and general management.

Classification of Textile Industry Value Chain:

- Physical value chain

- Virtual value chain

- Combined value chain

Global value chains (GVCs)

- Cross border / cross region value chains

- Global value chains (GVCs) indevelopment

Value Chain in Knit Industry:

- Almost complete value chain.

- Some of the factories fully integrated; spinning to finished garment.

- Core strength is backward linkage.

- 95% knit fabric produced locally.

- Cumulative average growth of knitwear is 27%.

Value Chain in Woven Industry:

- Only a few woven factories that offer quality product.

- Majority fabrics has to be imported-higher purchasing cost dependency on external supplier, pricing disadvantages, No GSP facilities for imported fabrics.

- Annual consumption of fabric is 3 billion yards.

- Consumption increasing 20% per year.

You may also like:

- How to Calculate the Overall Equipment Effectiveness (OEE) of Apparel Industries

- Line Balancing and Bottleneck in Garment Production Line

- Industrial Engineering Formulas for Textile Students and Professionals

- Line Balancing and Bottleneck in Garment Production Line

- How to Determine Seam Strength in Garment Industries

- How to Calculate the Overall Equipment Effectiveness (OEE) of Apparel Industries

- Method Study in Apparel Industry – A Systematic Approach

- Benefits of Work Study in Garments Industry

- Application of Lean Manufacturing in Garment Industry

- Concept of ISO 9000, Six Sigma and Lean Production for Apparel Industry

- Lean Manufacturing Process in Apparel Industry

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. Mr. Kiron is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.