Selvedge Formation Techniques in Woven Fabrics

Manohar D Agasthya

Govt Institute of Textile Technology, Bangalore, India

Email: manusamarth00@gmail.com

Selvedge:

The warp way strip which form’s the edge of a peace of cloth is known as selvedge. Selvedge is the edges of both sides of the fabric along the parallelly fabric length. The basic function of any selvedge in woven fabrics is to lock the outside warp threads of a piece of cloth and so prevent fraying. The selvedge should have a neat and uniform appearance.

It serves the following purposes:

- To bind at least one of the extreme ends with the weft for preventing fraying of the cloth.

- To provide extra strength in the edge’s where the cloth is held by clips in the subsequent finishing process.

- To provide end capable of withstanding of greater abrasion by the reed occurring at the edges of the warp.

- To provide space for ornamentation as in saree or dhoti identification.

According to the interlacing or the type of loom these are classified into two types namely:

- Conventional selvedge

- Unconventional selvedge

Conventional selvedge :-

It is formed because the shuttle contains enough weft for several picks ,and picking motion is arranged in both the side of the loom.

Unconventional selvedge:-

It is employed in the conventional loom like rapier, air jet, projectile weaving, as the picking mechanism is arranged only at one side of the loom .

Four types of selvedges can be formed:

- Tucked-in selvedges

- Chain stitch selvedge

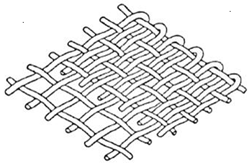

- Leno selvedges

- Fused selvedges

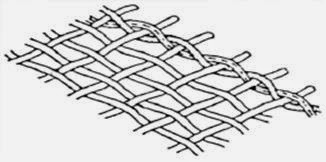

1. Tucked in selvedge:-

A special hooked needle driven by a cam produces, after cutting the insertion of the producing thread end into the subsequent shed, thus forming a strong edge.

2. Chain stitch selvedge:-

These type of selvedge are mostly produced in shuttle less narrow fabric weaving mechanism in which the picking takes place by means of needle.

3. Leno selvedge :-

These selvedge are obtained by binding the weft with strong additional threads working in gauze weave and by eliminating through cutting the protruding weft ends.

4. Fused selvedge:-

These are obtained by pressing a hot mechanical elements on the fabric edge. Some times used to split the wider fabrics into narrow fabrics.

You may also like:

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.