Airbag for Automobiles

Moin.S Khan

DKTE’s Textile and Engineering Institute,

Ichalkaranji, Maharashtra, India

Email: moinkhn024@gmail.com

Introduction

The term automobile means all kind of textile component e.g. fibers, filament, yarn and fabric used in transportation like cars, train, buses, air planes and marine vehicles. Over 15-20 different kinds of fabric are used in automobiles. Automotive textiles are engineered fabrics to meet the challenges of an increasingly competitive automobile manufacturer requirement. Textiles provide a means of decoration and a warm soft touch to the seats and the interior of the car, but they are also used in more functional applications. The automobile industry is the largest user of technical textiles, with about 20 kg in each of the 45 million or so cars made every year world-wide. The automobiles industry has started in the late 1950’s to research on airbag and the first invented version was patented on 1953. Then, Air bags have been commercially available since late 1980’s. The technological difficulty leads to the 30-year span between the first patent and the common availability of the airbags. Airbags have even been suggested for protection of the head. Knees and legs. Rear passenger airbags are being developed as well as side airbags which provide protection in roll-over accidents by shielding the occupants from side window glass and protecting the head.

A recent study shows that there is a significantly higher reduction in moderate to serious head injuries for people using airbags and seat belts together than for people using only seat belts, when compared to drivers using no restraining safety equipment. The study also says that deaths among drivers using both airbags and seat belts are 26% lower than among drivers using seat belts alone. Airbag market is growing very rapidly in the Western Europe and in USA and become that airbag is mandatory in the newly produced cars. They are designed to act as the supplemental safety device in addition to the seat belts.

Objectives of Airbag

The main objective of an air bag is to lower the number of injuries by reducing the fore exerted by steering wheel and the dashboard or any point on the body. This is accomplished in two ways:

- By increasing the interval over the force being applied

- By spreading the fore over a large area of the body

The airbag system has been engineered to work with the pressure between the passenger and steering wheel, in a fraction of second. The airbag unit must also stay intact at low velocity collisions. The crash sensor, which detects the collisions and trigger the bag, to inflate must take all those constraints into account. The operation of deflation happens when N2 generation stops, gas molecules escape the bag through vents. The pressure inside the bag decreases and the bag deflates slightly to create a soft cushion. By 2 seconds after the initial impact, the pressure inside the bag has reached atmospheric pressure.

Airbag in Automobiles

The use of airbag has expanded beyond frontal airbags for protecting the driver and passenger. Side airbags and inflatable curtains are now included in side compartments of vehicles and leg airbag for enhanced protection from side collisions or rollovers (8). The airbags depending upon their placement in the vehicle can be classified as:

- Front driver / passenger airbag – its capacity is 65 liters fill.

- Rear passenger’s side impact airbag – its capacity is 100 – 300 liter fill. They can be mounted in doors, seats, or sometimes even roof rails. Most side airbags are designed to protect people’s chests, and they’re likely to provide some head protection too.

- Knee bolster airbag for driver Thorax air bag for driver.

Materials and Properties of Airbags

Preferably airbag fabrics are sufficiently flexible to be able to be folded into relatively small volumes, but also sufficiently strong to withstand the deployment at high speed, e.g. under the influence of an explosive charge, and the impact of passengers or other influences when inflated.

Most important requirements of an airbag fabric is listed below:

- High Tensile strength

- High Tear strength

- Low Air permeability

- Good Heat capacity

- Good Folding behavior

- Better Energy absorption

- Good Coating adhesion

- Functionality at extreme hot and cold conditions

- Packagability

- Reduced skin abrasion (softness)

- Good heat stability

- Free of knots, splices, spots and broken ends.

The trends in the developments of the airbag system lie in reducing the weight of the airbag, in order to minimize injuries caused by the airbag itself. And also, the space needed by the airbag is reduced. This is achieved on one hand by the aforementioned reduction in mass and on the other hand by and improved air bag folding behavior.

Working Principle of Airbag

Crash test showed that for an airbag to be useful as protective device, the bag must deploy and inflate within the stipulated time. It takes only about 30-60 milliseconds to get activated at the event of collision. Airbags become energy-absorbing buffers between people and the hard interior surfaces of vehicles. Normally air bags are hidden in the hub of the steering wheel or in the dash on the passenger’s side as shown in figure no 1. Once the sensor has turned on the electrical circuit, a pallet of sodium azide (NaN3) is ignited, and a rapid reaction occurs, generating nitrogen gas. This gas fills a nylon or polyamide bag at a velocity of 150-230 miles per hour. In order for the air bag to cushion the head for maximum protection, the air bag must begin to deflate (decrease its interval pressure) by the time the body hits. Otherwise the high internal pressure of the airbag would create a surface as hard as stone – not the protective cushion.

Operation sequence of an airbag and chemical reactions

Inside the airbag is a gas generator containing a mixture of NaNO3, KNO3, and SiO2 . The signal from the deceleration sensor ignites the gas generator mixture by an electrical impulse when head-on collision, creating the high temperature conditions necessary for sodium asides to decompose at 300oC. This causes a relatively slow kind of detonation (Deflagration) that liberates a pre-calculated volume of N2 gas through series of chemical reaction, which fills the air bag. Please refer figure 2.

Reaction- (i)

2NaN3 → 2Na + 3N2

The sodium by product of this reaction, and the potassium nitrate generate additional N2, which also helps to fill airbag.

Reaction-(ii)

10Na + 2KNO3 → K2O + 5Na2O + N2

This reaction leaves potassium oxide and sodium oxide to react with the 3rd compound silicon dioxide, and forms alkaline silicate (“glass”), which is a safe and stable, unignitable compound.

Reaction-(iii)

K2O + Na2O + SiO2 → Alkaline silicate

NaNO3 is very toxic in nature (0.2 mg/m3 is only allowed in workplace) is been converted to alkaline silicate. The Na metal, which is explosive in nature, is been converted to alkaline silicate using KNO3 and SiO2.

Airbag Production Process

The following flow chart shows a typical manufacturing line airbag. Refer figure no 3.

Airbags can be manufactured by either of the mechanisms of fabric manufacturing, namely weaving and non-woven fabric manufacturing process.

Fabric contraction for airbags

Mostly used raw material for the airbag fabric is nylon 66 yarn in the deniers ranging from 420 to 840. The side impact airbags used 1880 D nylon-6.6. Table no. 1 shows the type, denier, GSM, stiffness etc. these fabrics are generally woven with the constriction of:

- 840 X 840 D, 98 X 98 /dm plain weave, 60” width.

- 420 X 420 D, 193 X 193 /dm plain weave, 60” width.

Table 1: constructional detail of fabric

| Type of airbag | Neoprene coated | Non- coated | Silicone coated | ||

| Yarns | Nylon 6.6 | Nylon 6.6 | Nylon 6.6 | Nylon 6.6 | Nylon 6.6 |

| Denier | 840 | 420 | 840 | 420 | 420 |

| EPI | 98 | 193 | 32 | 57 | 46 |

| PPI | 98 | 793 | 32 | 51 | 46 |

| GSM | 280 | 260 | 252 | 238 | 175 |

| Thickness (mm) | 0.38 | 0.34 | 0.4 | 0.35 | 0.25 |

Commonly, the airbag made were coated by neoprene, but recently silicon coated and uncoated varieties have become popular. Coated airbag are generally preferred for driver seats. The weight per unit length uncoated one is higher than coated bags, i.e. 244 to 257 Vs 175 g/m2. Usually Rapier with insertion rate of 400 m/min has been found most suitable for weaving airbags. Since, it can maintain warp tension with accuracy of 1 CN per warp. Even water jet and air jet with insertion rate of 600 m/min are being used.

Apart from the types of airbags have discussed above there are also some different types of airbags are being used i.e. Stitch Bonded Airbags, Laminated Airbag Substrate, Needle Punched Airbag Fabrics etc. most important type are discussed below.

Stitch bonded airbag

a low permeability stitch bonded fabric can be used for airbag. The proposed material has first and second surface comprising of a thermoplastic base web and a two bar warp knit structure. The bursting strength of the material is 2.5 MPa and the air permeability is controlled from the thermoplastic base web and is less that about 1 cm3/sec/cm2. To make the material the thermoplastic base web is fed into the stitch-bonding machine under tension and this in then reinforced by the two bar warp knit. Subsequently, it is calendared, the stitching should be 2-8 rows/cm. and with varying stitch density of 2-10 cm length. Stitching will usually be based on filament yarns such as polyamide or polyester. The back face of the fabric is stitched with anchoring pillars of the chain stitches with laid in weft yarns. These threads from pillars of chain stitches that are stitched through the thermoplastic base web (melt blown micro fibers based on aromatic polyurethane). The weft yarns are laid in passing behind the stitching needles in a pre determined pattern as the stitches are formed, but are retained on the technical back of the fabric.

Needle punched airbag fabrics

The permeability of fabrics intended for use in airbags, Needle punching can be used to increase, in a controlled manner Here the calendared fabric is given a multiplicity of needle punctures such that the puncture on one face is of a larger diameter than that on the other.

Different types of coating for the airbag substrate

Emulsion Coating

Methods of coating the substrates, comprises of water, continuous emulsion of a curable elastomeric polymer, and aqueous polyurethane dispersion, and an optional cure agent.

Polyorgano Siloxane Coating

A surface of the textile fabric is coated with first and second layers of polyorganosiloxane-based elastomeric material. The polyorganosiloxane-based material of the first layer exhibits an elongation-at-break of at least 400%. The polyorganosiloxane-based material of the second layer exhibits a tear-strength of at-least 30 KN/m. The benefit of using silicone-coated compositions over other, e.g. organic coating compositions, lies e.g. in the improved weather ability, ability to maintain flexibility and heat resistance of the silicone-based composition. Suitable curing conditions for the preferred compositions are 120 to 200oC. for a period of up to 5 minutes. The silicone coating primarily provides a thermal barrier on the airbags to protect the fabric from the high temperature burst associated with ignition of the gas upon deployment. The silicone coating also provides some gas retention properties for the deployed airbag.

Physical testing of coated and uncoated airbag

Two airbag fabric (coated and uncoated) with given constriction details have been tested for physical properties and following result were obtained. Table no. 2.

Table 2: Physical properties

| Parameters | Uncoated | Coated |

| (Epi x Ppi) | 25 x 25 | 25 x 25 |

| Thickness | 0.013 | 0.107 |

| Weight (oz / sq.yd) | 5.69 | 8.30 |

| Tensile strength: Warp Filling | 533 549 | 450 478 |

| Elongation: Warp Filling | 33.6 35.3 | 28 38 |

| Tongue tear: Warp Filling | 199.4 192.5 | 85 83 |

New Developments

Radial Deployment System (RDS)

Unlike traditional bags, Autoliv’s Umbrella RDS Bag has a ring of chambers that are filled with gas before the inflation of the middle section. Autoliv’s Umbrella RDS Bag deploys radially before it approaches the occupant. Under certain conditions, it reduces therefore the possibility for a short occupant sitting very close to the steering wheel of having the bag deploy below his or her chin figure no 4. Instead, the chances increase that the bag will cover the steering wheel in time, preventing injuries to the face and the head.

Lower Leg Airbag System

Autoliv’s Inflatable Carpet is a new protection system under development, which will protect the car occupant’s feet, ankles and lower legs in frontal crashes. It works by removing the feet from the intruding foot well of the vehicle. In simulated frontal crash tests, Autoliv’s Inflatable Carpet has been shown to reduce the critical parameters down to tolerable levels (e.g. reduction of foot acceleration by up to 65%).

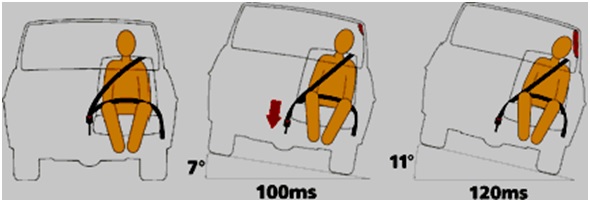

Rollover Protection:

Rollover accidents are a rapidly increasing problem due to the popularity of light trucks, sport utility vehicles and other vehicles with a higher centre of gravity. This causes a severe damage to occupants during rollover; this can be prevented by putting a side airbag as shown in the figure 6.

Conclusion

It is known fact, every innovation around on human beings needs and safety which together giving high value in any product. Automobile industry is highly competent sector which needs to satisfy customer in all aspects like aesthetic, price and safety values. Airbag is one of the inevitable components in automobiles specially in car and vehicles to safeguard drivers and passengers, hence knowledge about basic principle of working of airbags is important in manufacturing and also service sector. Automobile and Textile industry together provides many efforts to satisfy every customer.

References

- Prof. P.A. Khatwani, Mr. S.S. Yardi NCUTE- programme on “Technical textile”.

- S.Adanur, Wellington series “Handbook of industrial textiles”, Technomic publishing,1995.

- Aravin P. Periyasamy,“Theory Behind In Air Bags Application in Automobiles”.

- Walter Fung And Mike Hardcastle ‘Textiles in automotive engineering’ Woodhead

- Publishing Limited.

- N.Arun, “Techncial Textiles: Weaving Techniques”, the Indian Textile Journal, May 2001.

- http://auto.howstuffworks.com/airbag1.html

- http://www.ktca.org/newtons/9/airbags.html

- http://www.lemurzone.com/airbag/crash.html

You may also like:

- Aerospace Textiles: Raw Materials and Applications

- Protective Textiles with Its Enormous Applications

- Types of Protective Clothing and Their Uses

- Ballistic Protective Textiles – An Overview

- Knitted Space Suits: Protective Wear for Future

- Protective Clothing for Space Shuttle Traveler

- Applications of Smart Textiles for Protective Purposes

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. Mr. Kiron is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.