Types of Seam Used in Garments Manufacturing

Arman Hossain Akash

Department of Textile Engineering

Ahsanullah University of Science & Technology, Dhaka, Bangladesh

Email: armanakash899@gmail.com

What is Seam?

A line along which two or more fabrics are joined by sewing. The application of a series of stitches or stitch types to one or several thicknesses of material.

Properties of Seam:

Appearance:

Seam should be as flat as possible. There will be no defective view of stitches, seam pucker or unsightly view.

Performance:

- Seam Strength: Seam strength should be lower or equal of the fabric strength.

- Seam Elasticity: Seam elasticity should be higher or equal of the fabric.

- Seam Durability: Should be equal or higher than that of the fabric.

- Seam Security: During normal use of apparels, the seam should not fail due to simple reason. Confidence of normal stability of seam is the security of the seam.

- Seam Comfort: Should be comfortable and don’t create any problem during use.

Seam Classification:

According to British Standard 3870: 1991, seam is classified as-

- Class 1- superimposed

- Class 2- lapped

- Class 3- bound

- Class 4- flat

- Class 5- decorative/channel

- Class 6- edge neatening

- Class 7- applied

- Class 8- others (single ply constructions)

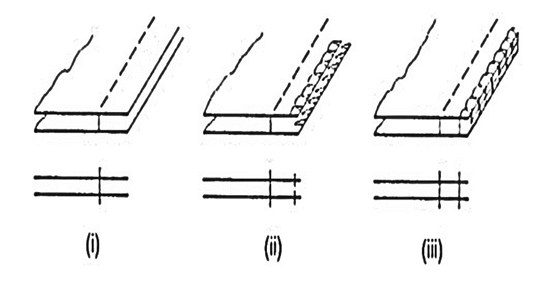

Superimposed seam:

This seam is constructed with a minimum of two pieces of fabric. One piece of fabric is fully imposed to another. The simplest seam type within the class is formed by superimposing the edge of one piece of material on another. A variety of stitch types can be used on this type of seam, both for joining the fabrics and for neatening the edges or for achieving both simultaneously.

The seams shown in Figs (i) and (ii) can be pressed open; that shown in Fig.(iii)

An example of this is the types of superimposed seam known as a French seam, which is completed in two stages. A similar, and in many cases equally acceptable, seam could be constructed using a folding device and a multi-needle machine, though only on a straight, rather than a curved, fabric edge.

An example of a superimposed seam with an additional component would be one that contained an inserted piping, and even here more than one construction is possible.

Lapped seam:

Lapped seam is made with two or more pieces of fabric overlapping each other. Lapped seams are common when sewing side seams on jeans and dress shirts.

Much more common on long seams on garments such as jeans and shirts is the so-called lap-felled seam, sewn with two rows of stitches on a twin needle machine equipped with a folding device.

The type of raised, top stitched seam often used down skirt panels is also technically a lapped seam, although at the beginning of its construction it appears to be a superimposed seam. It is often referred to as a welted or a raised.

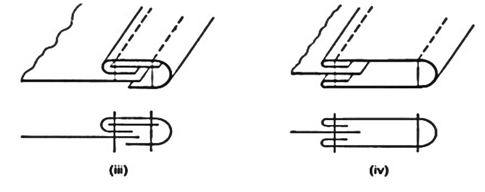

Bound seam:

A bound seam is one piece of fabric encompassing the raw edge of another piece of fabric. A bound seam is often used as a decorative edge and the binding may continue off the edge of the garment to provide tie ends.

Examples in common use on underwear and leisurewear and on skirts, jeans and ladies’ trousers are shown in above Fig. In part (i) is shown a common finish used on the neck edge of tee shirts, and also on the edges of men’s vests and briefs.

In Fig. (ii), there is an insert of another cut strip. This would normally be in a contrasting color to the garment and both could contrast with the outer binding.

In Fig. (iii), an elastic has been included in a sufficiently stretched state to draw the edge of the garment in to a snug fit.

In Fig.(iv), a waistband, usually with an interlining fused to it, is bound on to the top of a skirt, jean or trouser using a folder and twin needle machine. The ends of the waistband require stitching separately.

Flat seam:

In this class, seams are referred to as flat seams because the fabric edges do not overlap. They may be butted together without a gap and joined across by a stitch which has two needles sewing into each fabric and covering threads passing back and forth between these needles on both sides of the fabric.

Knitted fabrics are most commonly used because the advantage of this seam is that it provides a join that is free from bulk in garments worn close to the skin, such as knitted underwear.

Decorative seam:

This construction consists of a row or rows of stitches sewn through one or more plies of fabric.

Edge Neatening Seams:

This seam is used to prevent the edges of the fabric from rolling or curling. Seam types in this class include those where fabric edges are neatened by means of stitches (as opposed to binding with another or the same fabric), as well as folded hems and edges. The simplest is the fabric edge inside a garment which has been neatened with an overedge stitch.

In Fig. (i) is typical of the hem on a dress or a pair of trousers in a woven fabric, which has been neatened and then sewn up.

In (ii), a folding device is used in the construction of the hem of a shirt or a skirt lining; (iii) and (iv) show a method of folding an edge that is sometimes used on the buttonhole front of a shirt.

Applied seam (Class -7):

Seams in this class relate to the addition of separate items to the edge of a garment part. They are similar to the lapped seam except that the added component has a definite edge on both sides. Examples would be a band of lace attached to the lower edge of a slip as in Fig. (i),

Others (Class-8): Single Ply

The final seam class in the British Standard is another where only one piece of material need be involved in constructing the seam. The commonest seam types in this class is the belt loop as used on jeans, raincoats, etc. This is shown in Fig. (i). Also included in this class are belts themselves; two possible constructions for these are shown in Fig. (ii) and (iii)

You may also like:

- How to Determine Seam Strength in Garment Industries

- Procedure of Fabric Seam Slippage Test

- Seam Defects | Common Seam Quality Defects in Garments

- Scope of Seam Engineering to Increase the Seam Strength by Controlling Different Parameters

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. Mr. Kiron is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.

Useful information for apparel manufacturing.