Sustainable Textile Dyeing Using Condensation-Purified Seawater: An Eco-Friendly Approach to Reduce Industrial Freshwater Consumption

Mst Taiyeba Akon Borsha

Aman Ullah College, Baridhara, Radhanagar, Bhandaria, Pirojpur

Email: borshataiyeba@gmail.com

Abstract

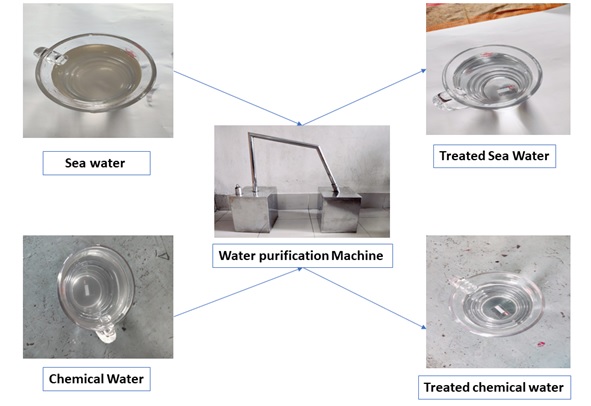

This project is done to reduce the uses of deep water and reuse the chemical mixed water & sea water. We can see how much water drained out from an industry per day and there is a huge source of water in sea. Our main goal is to use that water in industrial operation in the place of chemically obtained soft water. For that operation we had to build a machine of stainless steel which can purify the sea water by condensation process. Then we dyed three different shades with that purified water. Water Hardness & pH is tested for the extracted water. For the dyed fabric we go for spectrophotometer color assessment, color fastness to washing, color fastness to water, color fastness to rubbing, color fastness to light, color fastness to perspiration. The obtained results are very much satisfying. This research is environment friendly and will save water source for further generation.

1. Introduction

We are unable to envision a day without water because it is necessary for human life. Water shortages pose a threat to peoples’ ability to live healthy lives. It is believed that rising salinity and tainted water are negatively influencing human existence. For all life on Earth, water is one of the most important natural resources. Water availability and quality have always been crucial factors in deciding not only where people might live but also how happy those lives will be. Only 28% of the nation’s total utilizable water resource, or around 1123 BCM, comes from precipitation (690 BCM from the surface and 433 BCM from the ground)[1]. Bangladesh’s water situation is getting worse as a result of population increase and modernisation demands. Bangladesh is a land of rivers, lower riparian areas, and abundant natural resources. For living, farming, and industrial uses, it primarily relies on natural water supplies. Surface water serves as Bangladesh’s primary source of water[2]. Rivers are the primary supply of surface water, however they are increasingly decreasing flow. Because the production of textiles, including textile dyeing, washing, finishing, etc., uses a lot of surface water[3]. One of the top 10 water-using industries is the textile industry, which is a significant water consumer.

Various textile manufacturing steps, including preparation, size, desizing, scouring, bleaching, dyeing, printing, and value-added aesthetic and functional finishing, all need a significant amount of water. Depending on the precise operations carried out at the facility, the equipment utilized, and management practices regarding the use of water, the amount of water used in the textile industry varies greatly. About three times as much water is consumed in a process house as in all other units combined. In terms of the various natural textiles, the methods for making wool and other felted fabrics need more water than those for making woven, knit, stock, and carpet. When it comes to cotton textiles, 95% of the water is utilized to produce the raw materials, and the remaining 5% is used to process the cotton fabric. To process 1 kg of cotton textile, it is estimated that 100–150 L of water are required. Traditionally, it takes more water (greater water footprint) to create a pair of cotton jeans. Wool and silk, which are protein fibers, need more water overall because of scouring and coloring. It has recently been claimed that bleaching cellulosic cloth uses more water than other techniques. Different volumes of water are required for the intricate coloring process.

In the case of knit processing mills, it is observed that an average of 10 gallons of water are needed per pound of product, while water use can range from 2.4 gallons to 45.2 gallons. It has been noted that a significant amount of water is needed in practice to process textiles. But it differs from mill to mill based on a number of variables, including the fabric type, equipment type, manufacturing procedure, and dyestuff utilized. The washing machine uses a lot of water at the conclusion of each phase[4]. A single pair washing pants can require up to 10,000 liters of water, and a cotton shirt can require roughly 2,500 liters. In total, the industry is to blame for 20% of the world’s water pollution, which equates to 110 million people’s annual water needs. Since water makes up 71% of the surface of the planet, its amount is constant year after year. However, the oceans contain 97% salt water, leaving humanity with only 3% of fresh water. Considering that 2.5 percent of the water is now frozen, just 0.5 percent of fresh water is now fit for human consumption. Over 4 trillion cubic meters of freshwater are used annually globally. We have used more than 2,002 trillion cubic meters of fresh water since the year 2022. In addition to being used for human consumption, 70% of freshwater withdrawals are used for agriculture, 20% for industry, and the remaining 10% for household reasons. Country-to-country variations in water use are caused by a variety of reasons, including population expansion, industrialization, and agricultural use.

Bangladesh will thus have a major water crisis within the next two decades as a result of sporadic contamination of surface and ground water, a lack of comprehensive water sharing with neighbors, and poor management of rainwater collection. Bangladesh is harming its surface and ground water by dumping rubbish into water bodies and over-extracting ground water, even though the entire globe is considering seriously conserving their water resources to ensure water security[5]. In this case, we should reuse chemically mixed water and sea water instead of using as much groundwater. Despite the fact that numerous research papers on water treatment processes have been published, no research has been done to treat sea water or mix chemicals with water for the purpose of dyeing textiles. For that procedure, we had to construct a stainless steel machine that uses condensation to clean seawater.

2. Materials & Methods

2.1 Materials

Salt water which is known as sea water found in sea or ocean. In this study, this raw material was used to purification water. Here, stainless steel (Winner Stainless Steel Mills Ltd, Prime Market, Dhaka), Cotton fabric (Best Fabric Textiles, Dhaka), Reactive dye (Lucent Color Effect Ltd, Muktijodha Sharani Road, Dhaka), Glauber salt (AlK TkdeirhCo.Ltd, Sonargaon, Dhaka), Sodaash (Regent Chemicals Co. Ltd, Dhaka). All reagents were used without further purification.

2.2 Methods

First of all, both pots were rinsed & spin off with tap water. Sea water was inserted through the upper nozzle of the pot, which was made of stainless steel. The nozzle then closed with a cap and outer side was covered with couple layers of gum. The connected pipe line of the pot which was heated, inserted in the other pot where the pure water was collected. The joining of the pipe line was tightly sealed with gum. Later the pot which contained the sea water placed on a gas burner. Other pot was placed in a big bowl & cold water around its outer layer. then sea water started boiling, above 100◦C water started vaporizing. The water vapor went through the pipe line leaving other chemical compound which was mixed with it. The pipe line was covered with fabric, which was wet with cold water. Thus, the temperature of water vapor reduced in its way through pipeline. These vapor then entered in the empty pot which was previously placed in cold water containing bowl. Thus, the vapor condensed into water. The obtained water then collected in a bottle.

Test for color fastness to washing

The test is carried out as per ISO 105 C06 (A2S) -2010 method. In this test the different dyed fabric were cut into pieces of 10×4 cm and placed between three shade of undyed fabric (red, brown, blue) of same size all four layers were sewn from all side this is said to be the bread type of arrangement of fabrics. The washing is done by 4% non-ionic soap solution for 30 minutes using washing fastness tester (Laundrometer) using 50 steel balls. The samples were rinsed in running water and dried in shade and then assessed with the help of grey scale ISO 105 A02 and ISO 105 A03 for loss of shade and extent of staining.

Test for color fastness to water

The test is carried out as per ISO 105 E01 -2013 method. In this test the different dyed fabric were cut into pieces of 10×4 cm and placed between three shade of undyed fabric (red, brown, blue) if same size all four layers were sewn form all side this is said to be the bread type of arrangement of fabrics. The washing is done 4% non -ionic soap solution for 30 minutes using washing fastness tester (Laundrometer) using 50 steel balls. The samples were rinsed in running water and dried in shade and then assessed with the help of grey scale ISO 105 A02 and ISO 105 A03 for loss of shade and extent of staining.

Test for color fastness to Rubbing

This test was done as per ISO 105 – X12-2016 method using crock meter. A piece of cotton was rubbed 10 times on a sample with the help of crock meter. Two types of rubbing were done, wet Rubbing and dry Rubbing. The staining on the wet and dry piece of fabric is evaluated with the help of grey scale as per ISO -105- A03

Test for color fastness to light

This test is carried out as per ISO 105 – B02 -2014 method. The dyed samples of 2×3 cm were fixed on a test assessment sheet in such a way that all samples were half exposed and half unexposed. This frame was placed inside the fadeometer fitted with Xenon Arc fading lamp. The specimens were brought out after 48 hours and color fading was assessed against the blue cotton standards ISO -105-A03

Test for color fastness to perspiration

The test is carried out as per ISO 105 E04-2013 method. The dyed samples of 10×4 cm were fixed on a test assessment sheet in such a way that all samples were half alkali & half acid. Here, all four layers were sewn from all side this is said to be the bread type of arrangement of fabrics. The sample assessed with the help of grey scale (ISO 105 A02) for change in color and (ISO 105 A03) for staining of the adjacent fabric.

3. Result & Discussion

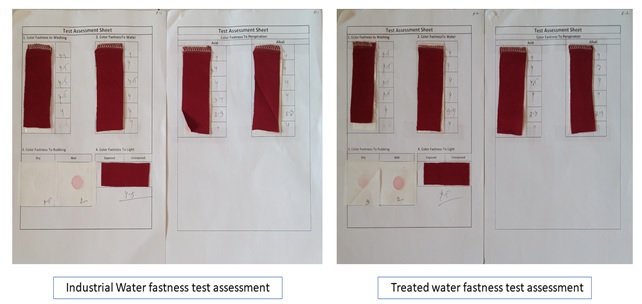

The preliminary experiments shows that the treated of our water & industrial water yield a wide range of dyeing and so detail study was conducted to standardize the methods and application of different cotton shade (Red, brown, blue). The results obtained are discussed below.

pH: The treated water pH was tested as 6.26.

Water hardness: Hardness of the water remains between 3 – 4 ppm (ml/L).

Fastness Tests

Color fastness to washing:

The sample were assessed on the basis of change in color and staining on the adjacent fabric with the help of grey scale. The rating was given in Table-1. In case of Red, Brown, Blue shade, fastness grading range good to excellent (4-5) were obtained in industrial water dyeing and our treated water dyeing.

| Serial No | Multifiber stripe | State | Industrial water Rating | Treated water Rating |

| 01 | Di-acetate | Red | 4-5 | 4-5 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 02 | Cotton | Red | 4-5 | 4-5 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 03 | Nylon | Red | 4-5 | 4-5 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 04 | Polyester | Red | 4-5 | 4-5 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 05 | Acrylic | Red | 4 | 4 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 06 | Wool | Red | 4-5 | 4-5 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 |

Table 1: Rating of Fastness to washing for cotton shade (Red, brown, blue).

Color fastness to water:

The samples were assessed on the basis of change in color and staining on the adjacent fabrics with the help of grey scale. The rating is given in Table-2. On the basis of which it has been found that in cotton (Red, Brown, Blue). In case of Red fastness grading range were good (4) by industrial water dyeing and our treated water dyeing. In case of Brown fastness grading ranges good to excellent (4-5) were obtained in industrial water dyeing and our treated water dyeing. By reviewing the dyeing of these two shade (Red and Brown), it was seen that the quality of our treated water and industrial water were the same. In case of Blue, fastness grading ranges good to excellent in our treated water dyeing than industrial water dyeing.

| Serial No | Multifiber stripe | State | Industrial water Rating | Treated water Rating |

| 01 | Di-acetate | Red | 4 | 4 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 02 | Cotton | Red | 4 | 4 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 03 | Nylon | Red | 4-5 | 4 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 | ||

| 04 | Polyester | Red | 4 | 4 |

| Brown | 4-5 | 4-5 | ||

| Blue | 2-3 | 4-5 | ||

| 05 | Acrylic | Red | 4 | 3-4 |

| Brown | 4 | 4-5 | ||

| Blue | 4 | 4-5 | ||

| 06 | Wool | Red | 4 | 4 |

| Brown | 4-5 | 4-5 | ||

| Blue | 4-5 | 4-5 |

Table 2: Rating of Fastness to water for cotton shade (Red, brown, blue).

Color fastness to rubbing:

Color fastness to rubbing used to determine the stability the dyed color on the fabric. This test shows how the color staining has happened. If its value is more than 2-3, it is considered as good result and it is below 2-3, it is considered as poor result and if it is 2, it will be considered as acceptable. The rating is given in Table-3, on the basis of which it has been found that in cotton (Red, Brown , Blue). In case of Dry Rubbing, Red, Brown shows that excellent color staining (4-5) by the industrial water dyeing. On the other hand we show that good color staining in case of Red (3) and very good color staining in case of Brown (4) were obtained by our treated water dyeing. Secondly, Blue shade shows that very good color staining (4). By industrial water dyeing and our treated water dyeing. By reviewing the dyeing of these Blue color shade it was seen that the quality of our treated water was the same. Again in case of wet Rubbing, Red was acceptable color staining (2), Brown and Blue were obtained good color staining (3) in case of industrial water dyeing and our treated water dyeing.

| Serial No | Shade | State | Industrial water color staining | Treated water color staining |

| 01 | Red | Dry | 4-5 | 3 |

| Wet | 2 | 2 | ||

| 02 | Brown | Dry | 4-5 | 4 |

| Wet | 3 | 3 | ||

| 03 | Blue | Dry | 4 | 4 |

| Wet | 3 | 3 |

Table 3: Rating of Fastness to Rubbing for cotton shade (Red, brown, blue).

Color fastness to light:

Light is also a very important factor. Which effects the color, generally color get faded in sun light, so this test gives very important information that whether the color shade applied on fabric is stable to slight or not. So to perform these test dyed sample were placed in light more than 20 hour continuously. With this test, the change in color can be identified if fabric of different shades is placed under artificial light. In terms of color fastness to light 3 and 4 are acceptable because of the buyer’s requirements (4-5) are good to excellent results and 2 are considered as poor results. Table-4 indicates that for Red, Brown, Blue shade gave good to excellent result by the industrial water and our treated water dyeing.

| Serial No | Shade | State | Industrial water light color change | Treated water light color change |

| 01 | Red | Exposed | 4-5 | 4-5 |

| Unexposed | ||||

| 02 | Brown | Exposed | 4-5 | 4-5 |

| Unexposed | ||||

| 03 | Blue | Exposed | 4-5 | 4-5 |

| Unexposed |

Table 4: Rating of Fastness to Light for cotton shade (Red, brown, blue)

Color fastness to perspiration:

The color fastness to perspiration (acid and alkali) refers to the ability not to fade and not to stain when the dyed fabric is perspired on it. Here, fabric identify the change of color and multifiber stripe identify the color staining. All samples were half alkali and half acidic. In terms of color fastness perspiration, (3-4) above are acceptable because of the buyer’s requirements, below (3-4) report are very low, (4-5) are good to excellent. Table-5 indicates that for Red, Brown, Blue shade gave good to excellent result (4-5) of our treated water that of the industrial water dyeing.

| Serial | Multi fiber stripe | state | Industrial water color staining | Treated water color staining | ||||

| Red | Brown | Blue | Red | Brown | Blue | |||

| 01 | Di-acetate | Acid | 4 | 4-5 | 4-5 | 4 | 4-5 | 4-5 |

| Alkali | 4 | 4-5 | 4-5 | 4 | 4-5 | 4-5 | ||

| 02 | Cotton | Acid | 3-4 | 4-5 | 4-5 | 4 | 4-5 | 4-5 |

| Alkali | 4 | 4-5 | 4-5 | 3 | 4-5 | 4-5 | ||

| 03 | Nylon | Acid | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 |

| Alkali | 4 | 4-5 | 4-5 | 4 | 4-5 | 4-5 | ||

| 04 | Polyester | Acid | 3-4 | 4-5 | 3-4 | 4 | 4-5 | 4 |

| Alkali | 4 | 4-5 | 4 | 4 | 4-5 | 4-5 | ||

| 05 | Acrylic | Acid | 2-3 | 4-5 | 4-5 | 2-3 | 4-5 | 4-5 |

| Alkali | 2-3 | 4 | 4-5 | 2-3 | 4 | 4-5 | ||

| 06 | wool | Acid | 4 | 4-5 | 4-5 | 4 | 4-5 | 4-5 |

| Alkali | 4 | 4-5 | 4-5 | 4 | 4-5 | 4-5 | ||

Table 5: Rating of Fastness to perspiration for cotton shade (Red, brown, blue).

Dyeing:

100% Cotton fabric of 160 & 200 GSM is dyed with reactive dyes & our previously purified water. 3 shades of light, medium & dark is done respectively on blue, brown & red. Totally 6 sample is dyed, 2 sample per shade. One is dyed with previously purified water & another one is with industry soft water.

Light shade-

- Reactive Navy Blue: 0.60 g/l

- Reactive Br. Blue: 0.34 g/l

- Reactive Red: 0.264 g/l

- Glauber Salt: 38 g/l

- Soda Ash: 15 g/l

Medium shade-

- Reactive Yellow: 1.70 g/l

- Reactive Blue: 0.316 g/l

- Reactive Red: 0.314 g/l

- Glauber Salt: 55 g/l

- Soda Ash: 15 g/l

Dark shade-

- Reactive Red: 4.64 g/l

- Reactive Blue: 0.36 g/l

- Reactive Yellow: 2.86 g/l

- Glauber Salt: 75 g/l

- Soda Ash: 20 g/l

- Temperature: 60 ◦C

- Time: 60 min

Data Color:

Data color value is measured comparing with industry soft water. Industry soft water dyed color is set as standard color & compared the purified sea water dyed fabric color.

Light shade (blue) –

| III/Obs | CMC Decision | CMC DE | DL* | Da* | Db* | DC* | DH* | Metamarism Index |

| D65 10 Deg | Pass | 0.12 | 0.04 | 0.00 | -0.20 | 0.20 | 0.01 | |

| F11 10 Deg | Pass | 0.14 | 0.02 | 0.01 | -0.25 | 0.24 | 0.03 | 0.05 |

| A 10 Deg | Pass | 0.14 | 0.02 | -0.08 | -0.23 | 0.24 | -0.02 | 0.08 |

Medium shade (brown) –

| III/Obs | CMC Decision | CMC DE | DL* | Da* | Db* | DC* | DH* | Metamarism Index |

| D65 10 Deg | Pass | 0.24 | -0.13 | -0.25 | -0.16 | -0.25 | 0.16 | |

| F11 10 Deg | Pass | 0.26 | -0.14 | -0.28 | -0.20 | -0.28 | 0.19 | 0.05 |

| A 10 Deg | Pass | 0.22 | -0.17 | -0.26 | -0.21 | -0.31 | 0.13 | 0.06 |

Dark shade (red) –

| III/Obs | CMC Decision | CMC DE | DL* | Da* | Db* | DC* | DH* | Metamarism Index |

| D65 10 Deg | Pass | 0.12 | 0.16 | -0.06 | -0.05 | -0.07 | -0.02 | |

| F11 10 Deg | Pass | 0.11 | 0.15 | 0.02 | -0.07 | -0.02 | -0.07 | 0.10 |

| A 10 Deg | Pass | 0.10 | 0.15 | -0.09 | -0.07 | -0.12 | -0.01 | 0.07 |

Conclusion

Reusing wastewater presents issues because it hasn’t been properly treated. Finding such low-cost, low-tech, user-friendly ways that, on the one hand, avoid endangering our significant reliance on wastewater and, on the other hand, protect degradation of our priceless natural resources, is the task. The treatment method, color fastness to water, color fastness to wash, color fastness to Rubbing, color fastness to light, color fastness to perspiration & color matching results confirmed that very well treated of chemical water & sea water. This obtained water can be used very well in dyeing work and as the process is simple it will be possible to reduce their cost by using it in all industries.

References

[1] R. Singh Asiwal, S. Kumar Sar, S. Singh, and M. Sahu, “Wastewater Treatment by Effluent Treatment Plants,” Int. J. Civ. Eng., vol. 3, no. 12, pp. 19–24, 2016, doi: 10.14445/23488352/ijce-v3i12p105.

[2] K. Ahmed, A. M. M. M., & Roy, “Utilization and conservation of water resources in Bangladesh. Journal of Developments in Sustainable Agriculture,” 2007.

[3] S. Islam, “Water Scarcity and Conflict in Bangladesh: A Literature Review,” Soc. Chang., vol. 13, no. 4, pp. 85–106, 2019.

[4] K. K. Samanta, P. Pandit, P. Samanta, and S. Basak, Water consumption in textile processing and sustainable approaches for its conservation. Elsevier Ltd., 2018. doi: 10.1016/B978-0-08-102633-5.00003-8.

[5] A. Rajeswari, “Efficiency of effluent treatment plant and assessment of water quality parameters in tannery wastes,” vol. 5, no. 8, pp. 49–55, 2015.

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. Mr. Kiron is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.