Parts of Circular Knitting Machine with Their Functions

Apu Das

B.Sc. in Textile Technology, 2nd Batch

Textile Engineering College, Chittagong

Circular Knitting Machine:

Circular knitting machine is widely used throughout the knitting industry to produce fabric. It is designed to produce tube-shaped fabrics and come in various sizes (diameters) based on their field of application. This machine can be built in almost any reasonable diameter and the small diameter of up to five, which are used for wear. The performance of the circular knitting machine is affected by the elements such as frame, drive, yarn feeder, cam set-up, fabric takeup, yarn delivery device and monitoring and servicing devices. The needles and sinkers in these machines are arranged in a circle. The energy consumption per piece produced on a circular knitting machine is about five times lower than on a flat knitting machine using knit-to-shape function due to the higher productivity.

Machine for outerwear and under wear may vary from 12 inch to 60 inch in diameter according to manufactures requirement. This machine can be used either as fabric or for making garments completely with fancy stitch. Most of the circular knitting machine are used for the piece-goods trade. Latch needles are commonly employed in all modern circular machines because of their simple action and also their ability to process more types of yarn.

Important Parts of Circular Knitting Machine:

Circular knitting machine contains the following parts:

- Needle Track

- Needle

- Sinker

- Sinker Ring

- Creel

- Cone Holder

- VDQ Pulley

- Pulley Belt

- Brush

- Tension Disk

- Inlet and Outlet Stop Motion

- Yarn Guide

- MPF Wheel

- MPF

- Feeder Ring

- Disk Drum

- Pattern Wheel

- Feeder

- Cam Box

- Cam

- Lycra Attachment Device

- Lycra Stop Motion

- Cylinder

- Cylinder Balancer

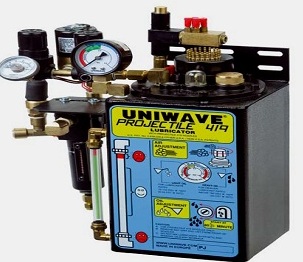

- Uniwave Lubrication

- Adjustable Fan

- Expander

- Needle Detector

- Air Gun Nozzle

- Cone holder

- Aluminum Telescopic Tube

- Winding Wheel & Driven Pulley

- Stopper

- Sensor

- Spreader

- Take-Down Motion Rollers

- Winding Roller

- Sinker Box

- Feeder Guide

- Fabric Detector

- Lubricating Tube

Important parts of circular machine are briefly described below.

1. Needle Track:

Where all Needles is placed together in a decent design.

2. Needle:

It is a principal element of the knitting machine. Needle receive yarn from the feeder, create a loop as well as release old loop and finally produce the fabric. Prior to yarn feeding the needle is raised to clear the old loop from the hook, and received the new loop above it on needle stem. The new loop is then enclosed in the needle hook as the needle starts to descend. The number of needles varies depending on the machine’s size and purpose.

3. Sinker:

It is the second primary knitting element. Sinker is a thin metal plate that rests behind the needles. It helps to loop forming, knocking over and holding down the loop.

4. Sinker Ring:

Sinker ring is a ring. Where all sinkers are pleased together.

5. Creel:

Creel is a part of a knitting machine. It is a vertical aluminium stick where creel is placed for holding the yarn cone. Hear yarn package are store and ready to feed in the machine.

6. Cone Holder:

Cone holder is the part of creel where the yarn cones are placed. It is an inclined metallic stick. It is also known as cone carrier.

7. VDQ Pulley:

VDQ means Variable Dia for Quality. It is a very important part of the machine. It controls the quality of knitted fabric by adjusting GSM and stitch length during the knitting process. Altering the position of the tension pulley changes the G.S.M. of the fabric. To increase the fabric GSM the pulley is moved towards the positive direction and to decrease the fabric GSM the pulley is moved towards the reverse direction. This pulley also called quality adjustment pulley (QAP) or Quality adjustment Disk (QAD).

8. Pulley Belt:

It controls the rotation of the MPF wheel.

9. Brush:

Its clean the pulley belt.

10. Tension Disk:

It confronts the tension of the supply yarn. It also ensures the appropriate gripping of yarn.

11. Inlet and Outlet Stop Motion:

It is an important part of the machine. It stops the machine instantly when a yarn is break.

12. Yarn Guide:

Its help the yarn to feed in the feeder.

13. MPF Wheel:

It controls the speed of the MPF. Pulley belt gives motion to the wheel.

14. MPF:

It is Mamenger positive feed. It is also an important part of the machine. It’s give positive feed to the machine.

15. Feeder Ring:

It is a ring. Where all feeders are pleased together.

16. Disk Drum:

Use in jacquard machine to produce various types of design.

17. Pattern Wheel:

Pattern Wheel use in Pai Lung and Auto Stripe machine because of that that help to produce various types of design and stripe.

18. Feeder:

Feeder is help yarn to feed in to the machine.

19. Cam Box:

Where the cam are set horizontally.

20. Cam:

Cam is device s which converts the rotary machine drive in to a suitable reciprocating action for the needles and other elements. Knitting cams are attached either individually or in unit form to a cam plate and depending upon the machine design.

21. Lycra Attachment Device:

Lycra is placed hear. And feeding to the machine. It has a con holder where Lycra filament cones are kept. There is an outlet sensor which sense if the Lycra out or break down.

22. Lycra Stop Motion:

It is one kind of stop motion to stop the machine when the Lycra is break.

23. Cylinder:

Needle track are situated hear. Cylinder holds the needle to its groove tightly. When it rotates the needle is also rotate.

24. Cylinder Balancer:

It helps the cylinder to set in a proper alignment.

25. Uniwave Lubrication:

The Uniwave lubricator provides uniform lubrication to needles, cam tracks, lifters and other knitting machine components. The patented nozzle construction separates the air-oil mixture into air and droplets of oil.

26. Take up roller:

Support the newly made fabric properly. So that newly made fabric can wound in cloth roller perfectly.

27. Expander:

To control the width of the knitted fabric. No distortion of the knitting courses. Even take down tension in the knitting machine. As a result, an even fabric structure is achieved over the entire fabric width. The deformation of the knitted fabric goods can be reduced.

28. Needle Detector:

This part detect the any type of faults of needles.

29. Fabric Detector:

If fabric torn off or fall down from the machine, fabric detector touches the cylinder and the machine becomes stopped. It also called fabric fault detector.

30. Air Gun Nozzle:

To feed the yarn; sometimes it is used for cleaning purpose.

31. Aluminum Telescopic Tube:

This is the tube through which yarn is passed from creel to the machine. It reaches the yarn to the Memminger positive feeder. It works as a yarn cover. It protects the yarn from the excessive friction, dust and fly fiber.

32. Knot catcher:

Clean the knot which made from dust.

33. Sensor:

The sensor is located at MPF. If anyone of the stoppers gets upwards due to the breakage of yarn, the sensor automatically receives signal and stops the machine.

34. Inlet sensor:

It sense during yarn breakage and stop the machine.

35. Outlet sensor:

It situated in the positive feeder at work is as like as inlet sensor. It sense when yarn breakage. Light glow. And the is machine stopped automatically.

36. Adjustable Fan:

Generally, two sets of running fans are continuously circulated from the center of machine dia. They remove lint, hairy fiber from yarn and others by air flow. To clean the dust by air flow. Adjustable fans are rotated in the opposite motion of the cylinder. It is situated upper position of cylinder.

Conclusion:

Circular knitting technology will lead the textile industry in producing special fabrics once the circular knitting machines are able to produce these fabrics at a high speed and of suitable quality, enabling competitive production of special and industrial fabrics for automotive and medical applications and elegant clothing. In this article I have explained various parts of circular knitting machine with pictures. If you have any query about this machine please let me know in comment section.

You may also like:

- Recent Development of Circular Knitting Machine

- Problems and Limitations of Circular Knitting Machines

- List of Fabric Defects in Circular Knitting Machine

- Production Calculation of Single Truck Single Jersey Circular Knitting Machine

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. Mr. Kiron is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.