What is Dispersing Agent?

Dispersing agent, also called dispersant known as chemicals that produce a stable aqueous dispersion of dyes of very low solubility. A dispersing agent is a non-ionic surfactant such as an alkyl-polyethyleneglycol. These are used to impart the leveling effect as well as to keep the dye in dispersed form, to avoid the dye aggregation and precipitation. It helps to increase dye solubility. Generally naphthalene sulphonic acid– formaldehyde condensate, lignin sulphonates and sulphonated oils are used in sulphur dyeing. Besides dispersing agents also anti-migration additives have to be used to prevent dyestuff redistribution during drying, which is called migration.

We can explain dispersing agent in comprehensively below:

Dispersing agents are substances that promote the more or less uniform and stable suspension of relatively small particles in a given matrix. The most common type of dispersion encountered in textile coloration, the solid-in-water systems typified especially by disperse dye technology, as well as the insoluble forms of vat and sulphur dyes. Pigments are also extremely important examples of solid-in-liquid dispersions. Specific types of dispersing agents, or mixtures are frequently needed to obtain the optimum dispersing action. There are two main groups of such agents:

- Surfactants, mainly of the anionic and nonionic types

- Water-soluble polyelectrolytes, most usually of the anionic type.

Disperse dyes are sparingly soluble in water; furthermore, the dyes, as synthesised, are often crystalline and of varying particle size. These characteristics are inadequate for practical purposes as difficulties will arise in dispersing the dyes in water and the resultant dyeings will be unlevel and weak. In order to achieve the required particle size and particle size distribution (commonly a maximum of less than 1µm) the disperse dye is milled, usually in the presence of a dispersing agent.

The dispersing agent, commonly anionic, ligninsulphonates or polycondensates of aryl sulphonic acids, facilitates milling by preventing agglomeration of the dye particles and enables the dye to be prepared in powder or liquid forms. Commonly, less dispersing agent is incorporated into disperse dyes prepared in liquid form than in powder form since the preparation of liquid brands entails less mechanical and thermal processing; also, liquid forms of the dyes are predispersed and therefore do not require to be redispersed in the dyebath.

Although the dispersing agent also facilitates dispersion of the dye in water, its main function, other than facilitating comminution of coarse dye particles, is to maintain a stable dispersion during dyeing. Additional dispersing agent is often added to the dye bath to maintain dispersion stability, especially in the case of liquid forms of the dye and when dyeing is carried out at high temperature.

You may also like: What is Sequestering Agent? | Types, Mechanism and Uses of Sequestering Agents

Dispersing agents are effective under the dyeing conditions and stable to hard water, high temperature and other dye assistants which help to maintain dispersion of dye molecule in the dye bath. Disperse dyes are insoluble in water and form aqueous dispersion in water. At first these dye molecules are formed as large particles and they are made smaller particles by grinding. But as they are water insoluble, they will give uneven dyeing if they are directly used in dye bath. So to ensure uniform and trouble free dyeing the dye should be present in dye bath in an uniform and very fine form and should give an stable dispersion. This is the reason for which a special chemical is used in dye bath named dispersing agent. They should be effective under dyeing conditions, stable to hard water, high temperature and other dyeing assistants.

For example, soap powder, Turkey Red oil, alkali sulphates, alkyl aryl sulphonates etc. are some surface active agents which are recommended as dispersing agents in disperse dyeing.

Functions of Dispersing Agents:

- It assists in the process of particle size reduction of dye.

- It enables the dye to be formed in powder form.

- It facilitates the recon version of the powder into a dispersion which is required for dyeing.

- It is not a surface active agent and hence has no wetting, foaming and detergent properties.

- It maintains the dispersion in a fine form in the dye bath through out the process.

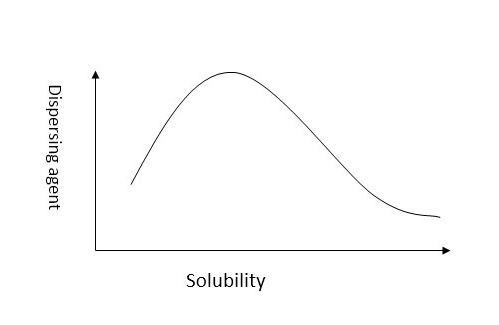

- It increases the solubility of disperse dyes in water.

- It is compatible with anionic and nonionic products.

- It affects on the rate of dyeing.

- It is resistant to alkali, acid and salt.

- When mixed with cationic produced in neutral and acidic medium then it may form precipitates.

You may also like: Working Process of Stabilizing Agent in Textile Wet Processing

Trade Names of Dispersing Agent:

- Setamol WS

- Edalon

- Hispogal

- Dispervat 60

- Dispersant WS

- Pidimol TD

- Nitamol NV- 50

- Uniperol AC

Examples of Dispersing Agent:

- Soap pawder

- Turkey red oil

- Alkel sulphonates

- Alkyl acryl sulphonates

- Formaldehyde

- Lignin sulphonates

References:

- Chemical Principles of Synthetic Fibre Dyeing by S. M. Burkinshaw

- Colorants and Auxiliaries (Second Edition) Volume 2 – Auxiliaries Edited by John Shore

- Textile Chemistry By Thomas Bechtold and Tung Pham

- Textile Dyes by N. N. Mahapatra

You may also like:

- Methods of Dyeing | Different Types of Dyeing Methods

- List of Chemicals and Auxiliaries Used in Textile Wet Processing

- Function of Salt in the Textile Wet Processing

- Effect of pH in Textile Wet Processing Industry

- Typical List of Chemicals Used in Dyeing Mill

- List of Garment Washing Chemicals and Their Functions

- Different Types of Textile Chemical Testing Procedure

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. Mr. Kiron is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.