Function of Carrier in Disperse Dyeing:

In case of dyeing with disperse dye, temperature plays an important role. For the swelling of fiber, temperature above 100°C is required if high temperature dyeing method is applied. Again in case of carrier dyeing method, this swelling occurs at 85–90°C. If it is kept for more time, then dye sublimation and loss of fabric strength may occur.

Carrier is an organic compound which accelerates dyeing by breaking up or dissolving dye aggregates and bringing them to the fiber-water interface in size small quantities enough to be absorbed by the material.

Disperse dyes are poorly soluble in hot water. The extreme crystalline nature of polyester fibers creates problems in obtaining dark shades by conventional dyeing methods even at high temperature. The carriers are found to assist the disperse dyes to enter the polyester polymer, enabling dark shades to be produced. The carriers swell the polyester fibers, increase inter polymer space and let the dye molecules to enter the polymer system easily.

You may also like: An Overview of Polyester and Polyester Dyeing

Recipe of Carrier Dyeing:

- Dye –

- For light shade<0.5%

- For medium shade 0.5-1.5%

- For deep shade>1.5%

- Carrier (phenol) : 3gm/lit

- Acetic acid : 1gm/lit

- Dispersing agent : 2gm/lit

- Salt (NH4)2SO4 : 1-2gm/lit

- pH :4-5.5

- M:L : 1:10

- Time : 60 min

- Temperature : 90°C

Carrier Dyeing Procedure:

- At first, a paste of dye and dispersing agent is prepared and then water is added to it.

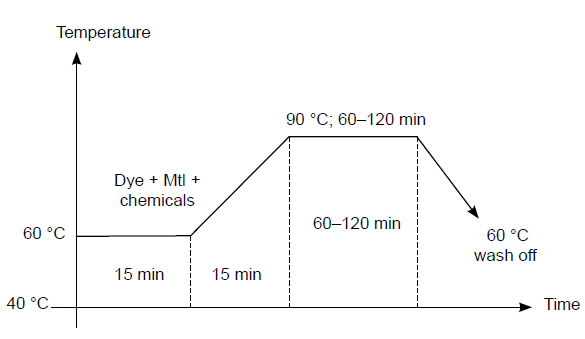

- Dye bath is kept at 60°C temperature and all the chemicals along with the material are added to it. Then the bath is kept for 15 min without raising the temperature.

- pH of bath is controlled by acetic acid at 4-5.5.

- Now temperature of dye bath is raised to 90°C and at that temperature the bath is kept for 60 min.

- Then temperature is lowered to 60°C and resist and reduction cleaning is done if required. Reduction cleaning is done only to improve the wash fastness.

- Material is again rinsed well after reduction cleaning and then dried.

Advantages of Carrier Dyeing Method:

- In conventional dyeing method, the extremely crystalline polyester fibers cannot be dyed in deep shade. But by using carrier we can get medium to dark shade in boiling temperature.

- Materials can be dyed with simple equipments at atmospheric pressure and temperature below 100°C.

- Moderate level dyeing of polyester fabric can be done.

- Some carriers reduce the staining of wool while dyeing polyester-wool blends.

- Rate of dyeing can be increased by using carriers.

- Can be dyed quickly by using carriers.

- Improves fastness properties of fabric except light fastness.

Disadvantages of Carrier Dyeing Method:

- Carriers add to production cost of dyeing. Firstly, for dyeing it is used which is costly and secondly for its removal alkali is required.

- Carriers are unhygienic and toxic. It creates skin diseases.

- Some dyeing machines may create carrier spot.

- Carriers affect the light fastness property of dyed material. This effect may be reduced by treating the material with hot air for 30 min.

- Some carriers are dyed specific. They posses different efficiencies with different dyes; others have compatibility with certain dyes.

You may also like:

- Commercial Name, Factors and Mechanism of Dyeing Carriers

- Polyester Fiber: Properties, Manufacturing and Applications

- Dyeing of Polyester Fabric with Disperse Dyes

- Printing of Polyester Fabric with Disperse Dyes

- To Improve the Wettability and Dyeability of Polyester and Polyester Blended (P/C) Fabric by Using Sericin

- Blending of Cotton-Polyester Fibre to Produce PC / CVC Yarn

- Dyeing of Cotton / Polyester Blended Knit Fabric with Reactive / Disperse Dyes Using Jet Dyeing

- Sustainable Recycled Polyester in Textile

- Polyester/Cotton (P/C) Blends Fabric Dyeing: Recipe, Parameters, Flowchart and Dyeing Curve

- Dyeing of Polyester Cotton Blended Fabric in Single Bath

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.